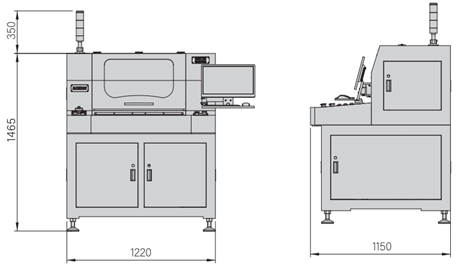

Dimension Drawing

Product Specifications

|

Item |

GAM330 |

GAM330L |

GAM330X |

|

Cutting Range |

300*350mm |

450*500mm |

470*650mm |

|

Cutting Function |

Straight line, L-shape, U-shape, circle, arc |

||

|

Work Table |

Dual Work Table |

||

|

Machine Repeatability |

±0.01mm |

||

|

Cutting Accuracy |

±0.05mm |

||

|

Maximum Moving Speed |

XY:1000mm/sec,Z:600mm/sec |

||

|

Maximum Travel Range |

X:800mm/Y:490mm/Z:90mm |

X:1090mm/Y:690mm/Z:90mm |

X:1090mm/Y:790mm/Z:90mm |

|

Spindle Speed |

MAX:100000rpm Adjustable |

||

|

Spindle Cutter Change Method |

Pneumatic Automatic Tool Change |

||

|

Cutter Detection |

With automatic tool breakage detection function |

||

|

Cutting Speed |

1-100mm/s Adjustable |

||

|

Operating System |

Windows 10 |

||

|

Program Teaching Method |

CCD image intuitive teaching input |

||

|

Control Method |

Precision Multi-axis Control System |

||

|

XYZ Axis Drive Method |

AC Servo Motor |

||

|

Applicable Cutter Size |

0.8-3.0mm |

||

|

Power Requirements |

AC220V 50/60Hz 2.2kW 1φ |

||

|

Air Source Requirements |

0.6MPa,50L/min |

||

|

Dimensions (W*D*H) |

1220*1150*1465mm |

1500*1497*1465mm |

1510*1650*1465mm |

|

Weight |

480kg |

600kg |

700kg |

|

Dust Collector |

TS200 |

TS200L |

TS200L |

Specifications are subject to change without notice. For special specification requirements, please contact us.

Optional Functions

·Safety Light Curtain

·Tool Diameter Detection

·Laser Height Measurement

·Barcode Reader

·MES System Integration