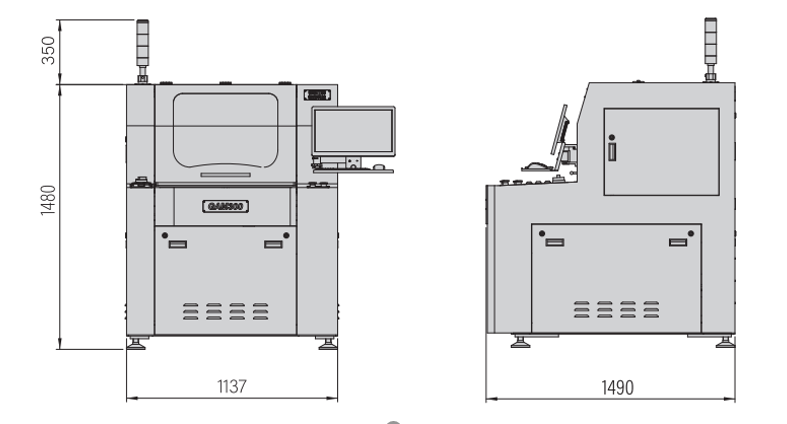

Dimension Diagram

Product Specifications

|

Item |

GAM320AT |

GAM330AT |

GAM340AT |

GAM360AT |

|

Cutting Range |

350*300mm |

350*300mm |

450*420mm |

600*500mm |

|

Feeding Method |

Rail Conveyance |

|||

|

Discharging Method |

Belt Conveyance or Rail Conveyance |

|||

|

Transfer Method |

Vacuum Nozzle Adsorption Transfer |

|||

|

Flow Direction |

Left to Right or Right to Left |

|||

|

Cutting Function |

Straight Line, L-Shape, U-Shape, Circle, Arc |

|||

|

Worktable |

Double Worktable |

Single Worktable |

||

|

Machine Repeatability |

±0.01mm |

|||

|

Cutting Accuracy |

±0.05mm |

|||

|

Maximum Movement Speed |

XY:1000mm/sec,Z:800mm/sec |

|||

|

Maximum Travel Distance |

X:790mm/Y:440mm/Z:90mm |

X:950mm/Y:440mm/Z:90mm |

X:1138mm/Y:597mm/Z:90mm |

X:1040mm/Y:655mm/Z:90mm |

|

Spindle Speed |

MAX:100000rpm Adjustable |

|||

|

Spindle Cutter Replacement Method |

Automatic Tool Change |

|||

|

Cutting Speed |

1-100mm/s Adjustable |

|||

|

Operating System |

Windows 10 |

|||

|

Programming Teaching Method |

CCD Image Intuitive Teaching Input |

|||

|

Program Backup |

USB Data Transfer |

|||

|

Control Method |

Precision Multi-Axis Control System |

|||

|

XYZ Axis Drive Method |

AC Servo Motor |

|||

|

Applicable Cutter Size |

0.8-3.0mm |

|||

|

Power Requirements |

AC220V 50/60Hz 4kW 1φ |

|||

|

Air Source Requirements |

0.6MPa,155L/min |

0.6MPa,160L/min |

0.6MPa,200L/min |

0.6MPa,220L/min |

|

Dimensions (W*D*H) |

1950*1192*1750mm |

2105*1445*1705mm |

2700*1567*1750mm |

2723*1604*1705mm |

|

Weight |

750kg |

800kg |

1000kg |

930kg |

|

Dust Collector |

TS200L |

TS300L |

TS300L |

TS300L |

Specifications are subject to change withoutprior notice. For special requirements, please contact us.

Optional Features

·Fixture module available for carrier process

·Laser height measurement

·Barcode reader

·Tool diameter detection

·MES customization